Intro

Warehousing and inventory management are a key part of many companies' operations, regardless of their industry or size. Therefore, it is not surprising that developing technologies are increasingly important in warehouse processes. One of the most important tools in this regard is WMS, or Warehouse Management Systems. In this article, we will take a look at what WMS Systems are, how they work and the benefits they bring to companies.

What are WMS Systems?

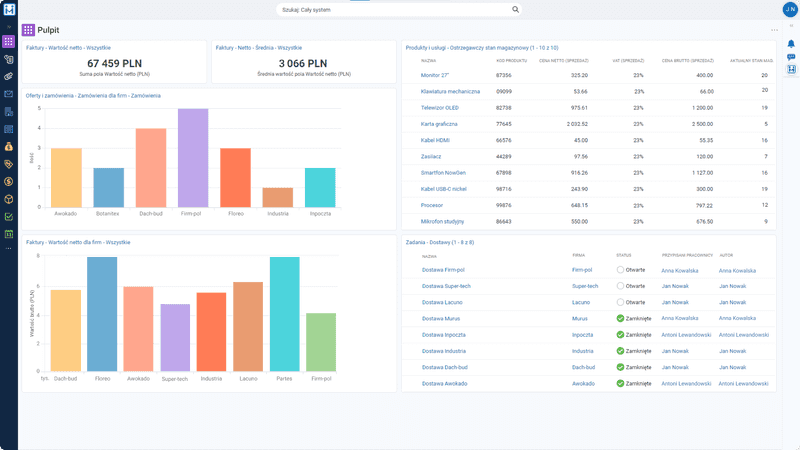

WMS systems are software designed to effectively manage a warehouse and control the flow of goods within it. Their main purpose is to optimize warehouse processes, reduce errors and increase efficiency. WMS systems provide a central control point for all warehouse-related activities.

WMS systems operate on the basis of data that is collected through various technologies, such as barcode scanners, RFID (Radio-Frequency Identification) or GPS systems. This data is then processed and analyzed by software that makes warehouse management decisions.

Main functions of WMS systems

- Space Optimization: WMS systems help optimize the placement of products in the warehouse, resulting in efficient use of available space.

- Inventory Management: By tracking incoming and outgoing goods, WMS systems allow you to accurately manage inventory levels, minimizing the risk of shortages or excesses.

- Monitoring Goods Movement: The software allows you to track every movement of goods in your warehouse, making it easier to identify any problems or delays.

- Order Management: WMS systems automate the order handling process, which reduces order processing time and minimizes errors.

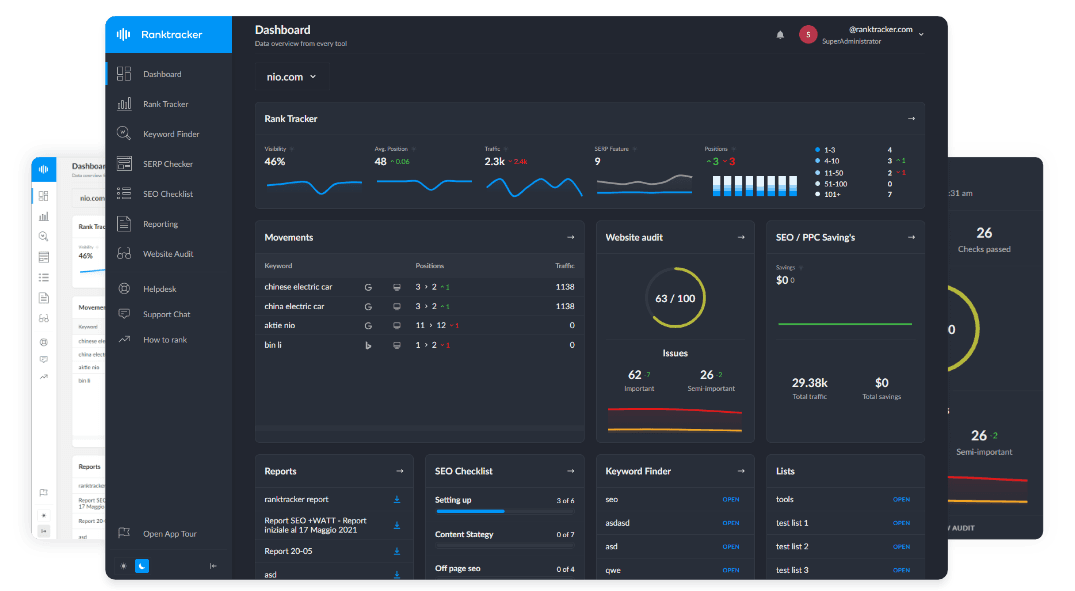

- Integration with Other Systems: WMS can be easily integrated with other systems, such as ERP (Enterprise Resource Planning) systems or TMS (Transportation Management Systems), allowing full control of the supply chain.

Key Steps of WMS Operation:

- Data Collection: Data on products, their location, quantity, date of receipt and release, and other parameters are collected and stored in a database using tools such as barcode scanners, RFID readers, or a dedicated package scanning system that ensures real-time visibility and tracking accuracy.

- Data Analysis: The WMS software analyzes the collected data, determining where and what products are stored and what orders are currently being processed.

- Scheduling and Control: Based on the analysis of the data, the WMS makes decisions about the placement of goods, assigning tasks to warehouse workers and managing time and priorities in order fulfillment.

- Monitoring and Reporting: As warehouse tasks are performed, the WMS monitors the progress of work and generates reports to track efficiency and detect any problems.

Benefits of implementing a WMS

Implementing a WMS brings many benefits to companies in the logistics and warehousing industry. Here are some of the most important ones:

- Increasing Productivity: WMS systems reduce order processing time and effectively manage employees and resources, leading to increased productivity.

- Reduction of Errors: Automation of warehouse processes minimizes the risk of human errors, which is important for accuracy and quality of customer service. Implementing automated warehouse systems further enhances efficiency by streamlining workflows, reducing manual labor, and ensuring real-time inventory tracking.

- Cost Optimization: Better management of inventory and warehouse space helps reduce costs associated with storing and transporting goods.

- Faster Response to Change: WMS systems enable rapid adaptation to market changes, new trends and customer needs.

- Better Control and Tracking: By accurately monitoring the movement of goods, companies have better control over their warehouse and supply chain.

Choosing a WMS - A Matter of Customization and Scalability

When choosing the right WMS, a company should consider its specific needs and expectations. There are many solutions available on the market, which vary in functionality and scalability. Therefore, it is worth thinking about whether the chosen system will be able to cope with the possible growth of the company's operations in the future. In addition, adapting the system to the specifics of your own warehouse and processes can be key to achieving maximum benefits. That's why it's a good idea to consult with experts or WMS providers to choose a solution that best meets your company's individual needs.

Summary

WMS systems are a key tool for companies involved in warehousing and logistics. By implementing them, you can achieve more efficient warehouse management, increase productivity, reduce errors and better control logistics processes. In an era of increasing competition and changing market demands, an investment in a WMS can prove essential to a company's success.