Intro

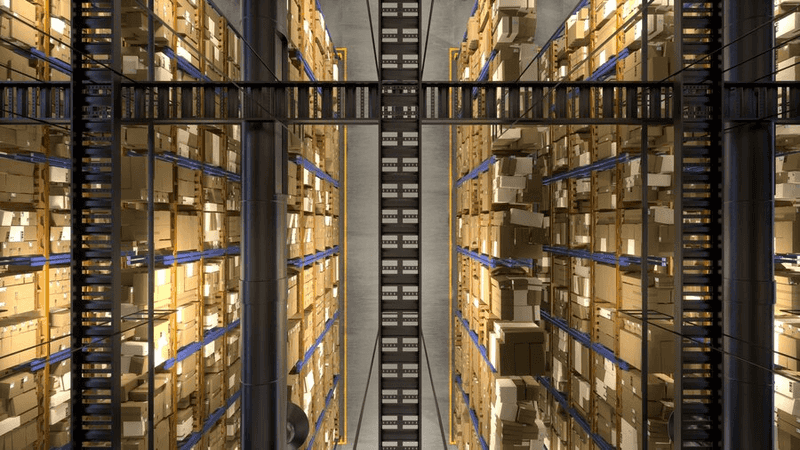

A 3PL, or third-party logistics provider, is a company that provides outsourced logistics services to businesses. 3PLs typically manage a company's warehousing and fulfillment operations. This allows companies to focus on their core competencies instead of the logistics behind getting their products to customers.

What is a 3PL?

A third-party logistics provider is a supply chain management company that handles logistics and fulfillment activities for other businesses. 3PL services typically include warehousing, transportation, inventory management, order processing, and fulfillment.

By outsourcing these critical supply chain functions to a 3PL, companies can better focus on their core business. Using warehousing 3PL and distribution services allows them to allocate more time and resources towards activities like sales, marketing, and product development.

According to industry estimates, 95% of 3PL providers agree that the use of 3PLs has contributed to improving service to the shippers’ customers. As global trade volumes continue to grow, the 3PL industry is expanding each year.

Benefits of Using a 3PL Warehouse

Outsourcing distribution and fulfillment to a dedicated 3PL warehouse provides many tangible benefits:

1. Cost Savings

Companies can achieve significant cost reduction by leveraging the economy of scale of a shared warehouse 3PL instead of handling logistics in-house. A 3PL consolidates inventory from multiple clients under one roof to reduce overhead costs per unit. High volume shipments also qualify for lower transportation rates. Companies like https://www.eliftech.com/logistics/ offer comprehensive 3PL solutions to streamline supply chain operations.

By not having to invest capital into buying or leasing warehouse space and equipment, companies can redirect those funds into core business investments. A variable “pay-as-you-go” 3PL pricing model also converts fixed costs into flexible operating expenses that scale up or down with changing business needs.

2. Improved Efficiency

Experienced 3PLs implement standardized best practices for receiving, putaway, replenishment, order processing, inventory control and shipping to enhance workflow efficiency. Increased productivity translates into faster order turnaround times, lower labor cost per order line and higher inventory accuracy.

They invest heavily into warehouse management systems (WMS), barcode scanning and other technologies to minimize errors and process automation. Their warehouse staff is professionally trained to operate optimally.

3. Flexibility

A good third party logistics provider offers flexible warehouse space and workforce to easily scale up or down as inventory and order volumes fluctuate. Companies avoid getting saddled with an under or oversized warehouse.

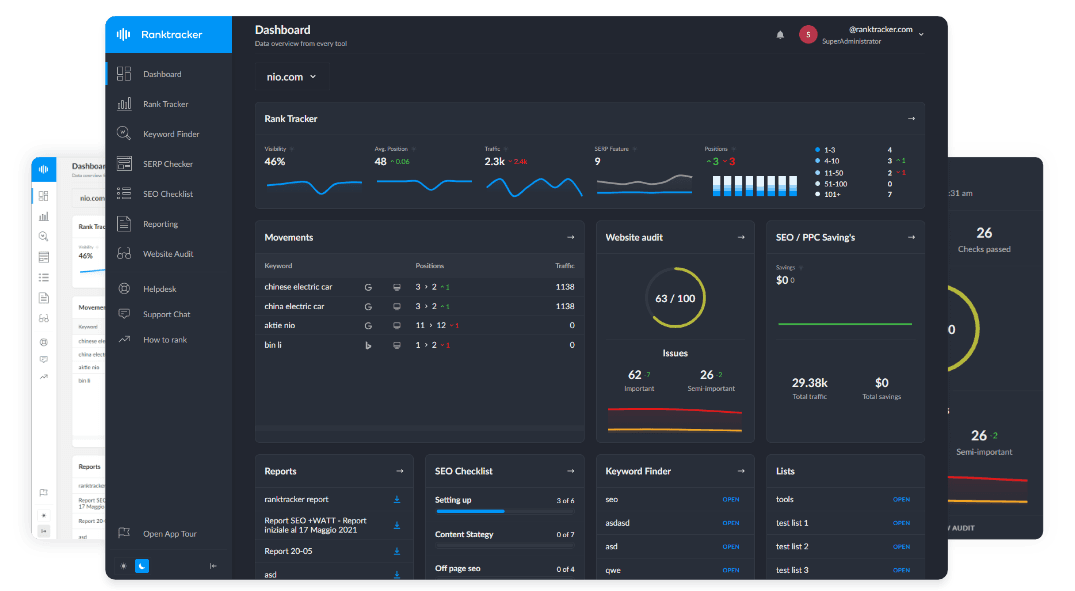

The All-in-One Platform for Effective SEO

Behind every successful business is a strong SEO campaign. But with countless optimization tools and techniques out there to choose from, it can be hard to know where to start. Well, fear no more, cause I've got just the thing to help. Presenting the Ranktracker all-in-one platform for effective SEO

We have finally opened registration to Ranktracker absolutely free!

Create a free accountOr Sign in using your credentials

During seasonal peaks, holiday sales and promotions, 3PLs can quickly ramp up storage capacity and labor. The abundant capacity allows them to readily onboard new clients as well. Companies can smoothly transition to a 3PL by starting small then gradually expanding the relationship.

4. Expertise and Technology

3PL warehouse operators have deep domain expertise from handling logistics for multitudes of companies across various industries. They stay on top of emerging technologies and best practices, including the integration of AI and IoT in supply chain management.

Most 3PLs have enterprise-grade Warehouse Management Systems (WMS), which provide real-time inventory visibility, directed put-away and picking, wave planning, and other advanced capabilities. They also utilize automation technologies like automated storage and retrieval systems.

This level of sophisticated software and automation provides professional-grade logistics infrastructure that most businesses cannot replicate in-house cost effectively.

Types of 3PL Providers

Not all third-party logistics companies are created equal. There is considerable diversity in services offered, types of technology used, industries served, geographic coverage and overall capabilities.

One way to differentiate them is by the scope of services provided:

1. Standard 3PL Providers

Standard 3PLs offer basic warehousing, distribution, transportation and freight services. This includes storage, picking and packing, shipping, rate negotiation and freight bill payment. They execute logistics functions as instructed without much customization.

This model works well for companies wanting simple outsourced logistics at low cost.

2. Service Developers

Service developers provide value-added services and specialized solutions tailored to customer needs beyond standard warehousing and transport. This includes kitting, product testing and repair, product labeling, returns processing, cross-docking and more.

They also provide greater integration with a company’s systems and processes through API connectivity. Service developers enable deeper strategic partnership.

3. Customer Adapters

Customer adapters go the extra mile to completely integrate services with the customer’s systems and processes. This level of synchronization demands information sharing, collaborative planning and process coordination between the 3PL and company.

The All-in-One Platform for Effective SEO

Behind every successful business is a strong SEO campaign. But with countless optimization tools and techniques out there to choose from, it can be hard to know where to start. Well, fear no more, cause I've got just the thing to help. Presenting the Ranktracker all-in-one platform for effective SEO

We have finally opened registration to Ranktracker absolutely free!

Create a free accountOr Sign in using your credentials

The 3PL adapts its warehouse management systems and operations to align with the customer’s existing workflows, instead of the other way around. This enables fully customized solutions.

4. Customer Developers

Customer developers co-design and co-develop logistics infrastructure and processes customized for the client. Solutions can include a dedicated warehouse facility, custom WMS configuration, tailor-made automation systems and more.

The All-in-One Platform for Effective SEO

Behind every successful business is a strong SEO campaign. But with countless optimization tools and techniques out there to choose from, it can be hard to know where to start. Well, fear no more, cause I've got just the thing to help. Presenting the Ranktracker all-in-one platform for effective SEO

We have finally opened registration to Ranktracker absolutely free!

Create a free accountOr Sign in using your credentials

This is the deepest level of strategic partnership, where the 3PL essentially helps build out the ideal logistics operation for the customer. Large 3PLs with extensive resources are more likely to offer customer developer partnerships.

Key 3PL Warehouse Services

Third-party logistics encompasses a vast range of services, though most 3PL warehouse providers offer some variation of these core offerings:

Transportation Management

Transportation management includes planning and execution of importing goods from suppliers overseas as well as exporting finished products domestically to customers. This involves coordinating freight via ocean, air and ground transport depending on the urgency, nature of goods and location of origin/destination.

Specific activities include:

- Negotiating contracted freight rates and consolidation opportunities across transportation modes.

- Managing customs clearance, document preparation and regulatory compliance.

- Coordinating deconsolidation of imported consolidated freight into individual customer orders.

- Final mile delivery of LTL shipments.

- Tracking inland transportation from port or ramp to warehouse.

- Scheduling trucks/rail for outbound shipments.

- Providing updates on order status and expected delivery date.

Inventory Management

Inventory management ensures optimal stocking levels and inventory accountability through:

- Reserving necessary warehouse storage capacity based on demand forecasts and inventory replenishment planning.

- Receiving purchase order deliveries from vendors along with quality inspection, discrepancy reporting, and putting away items in correct storage zones/bins based on SKU attributes and turnover.

- A cycle counting program for regular inventory record audits is used to maintain accuracy.

- Reporting key inventory metrics like average daily inventory, days on hand, inventory turns, etc.

- Identifying and managing excess stock, obsolete items, customer returns and other inventory exceptions.

- Issuing stock transfers, intra-warehouse movements and inventory reservations as needed.

- Replenishing pick faces in forward pick areas to align with order demand.

Picking and Packing

To fulfill orders accurately and efficiently, 3PLs optimize picking workflow through:

- Batching orders across multiple customers into waves based on delivery lead times, destination zone and other parameters.

- Optimizing picker routing through the warehouse to minimize travel distance and time.

- Directing put-walls, pick-to-light systems and pick-to-voice technology to enable accurate, rapid picks.

- Providing appropriate packaging materials to protect product condition and integrity.

- Applying compliance labeling like expiration dates, lot numbers, fragile stickers etc.

- Generating packing slips and other documentation needed for shipment.

Cross-docking

Cross-docking allows rapid product flow through the warehouse without extra put away and pick steps by:

- Unloading LTL volumes directly from inbound trailers and simultaneously prepping them for customer-specific outbound shipping.

- Consolidating less-than-truckload shipments from multiple vendors into full truckloads for common destination zones.

- Minimizing touches, temporary storage and material handling to enable faster fulfillment.

Ecommerce Order Fulfillment

To effectively support direct-to-consumer ecommerce channels, 3PLs provide:

- Seamless integration with website order management platforms.

- High-volume processing of multi-line orders with the ability to support extreme order spikes during promotions and holiday peaks.

- Shorter order cut-off times for same-day shipping and next-day delivery.

- Higher accuracy requirements with customer-ready packaging vs. bulk shipping.

- Retail-specific services like gift messaging, branded packaging, inserts/collateral, special kitting etc.

The wide spectrum of services and capabilities makes choosing the right 3PL partner extremely important. Assess both current and future needs to select a 3PL equipped to scale alongside business growth.

How to Select a 3PL Logistics Partner

Choosing the right third-party logistics provider is critical for outsourcing success. Here are key criteria to evaluate prospective 3PL partners:

1. Services Offered

The 3PL must offer the menu of required services like standard warehousing and distribution, fulfillment, crossdocking, transportation etc. Will they also provide value-added services relevant to your operations? Can they tailor solutions to your needs?

2. Location and Facilities

Ideally the 3PL warehouse location allows one-day ground delivery access to the majority of your customers. Their facility should have sufficient handling and storage capacity for your business needs today as well as headroom to accommodate future growth.

3. Technology and Automation

Evaluate if the 3PL’s warehouse management system, inventory control and order processing technologies can integrate with your ERP and order management platforms. What level of barcode scanning, RFID, and automation does their facility offer?

4. Experience and Expertise

Find a 3PL with extensive experience handling logistics for your specific product type and industry. For example, food and beverage products have unique warehousing requirements compared to consumer electronics. Ask for their track record with current customers of similar scale and operations.

5. Cost

While it’s important to keep costs low, the cheapest 3PL option may underdeliver on service levels. Seek optimal value at a fair price point. Negotiate rates after completely understanding the level of service expectations, liabilities and risks.

6. Scalability and Flexibility

Examine if the 3PL can readily scale up warehouse capacity, labor and systems to accommodate rapid sales growth, new product launches and seasonal spikes in your business. Can they smoothly transition initial pilot programs to full production rollout?

Choosing the right third party logistics partner requires thorough due diligence across these criteria specific to your business situation and strategic objectives. Take the time upfront to evaluate various 3PL alternatives before committing long term.

Key Steps for Implementing a 3PL Partnership

Once the 3PL selection process is complete, the real work begins to onboard them as an integral logistics partner. Follow these best practices:

- Establish an implementation team. Appoint representatives from company leadership, operations, sales and IT to clearly define requirements and coordinate 3PL onboarding.

- Set objectives and KPIs. Agree with the 3PL on specific metrics like fill rate, order accuracy, lead times, and inventory turns to track operational performance.

- Integrate systems and data. Ensure the 3PL’s warehouse management and order processing systems integrate seamlessly with your order management, ERP and inventory platforms.

- Define workflows. Document detailed protocols and procedures for warehouse receiving, put-away rules, inventory counts, order allocation rules, customer shipment preparation, returns and more.

- Conduct pilot testing. Before fully transitioning logistics operations, various fulfillment scenarios on a small subset of SKUs and orders must be run to prove the 3PL’s onboarding.

- Communicate change management. Notify all internal teams and external customers of the pending change in logistics operations and set their expectations accordingly.

- Maintain governance routines. Have frequent check-in meetings between the company and 3PL executives. Review KPI reports, discuss process improvements, plan for upcoming retail peaks, and align with the technology roadmap.

By investing diligently upfront in implementing third party logistics, companies can maximize ROI on outsourcing critical distribution and fulfillment operations. Choose the right 3PL partner then collaborate closely with them for operational excellence.